Novel Rotary Electrical Contact Eliminates Reliance On Rare-Earth Magnets for Large-Scale Wind Turbineshttps://newsreleases.sandia.gov/turbine_innovation/

Motivated by the need to eliminate expensive rare-earth magnets in utility-scale direct-drive wind turbines, Sandia National Laboratories researchers developed a fundamentally new type of rotary electrical contact. Sandia is now ready to partner with the renewable energy industry to develop the next generation of direct-drive wind turbines.

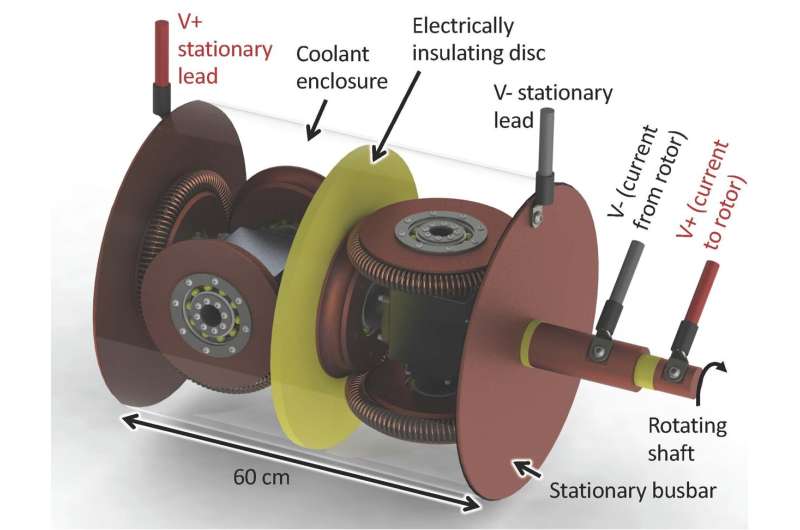

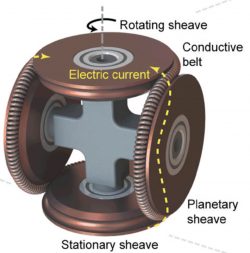

Sandia's Twistact technology takes a novel approach to transmitting electrical current between a stationary and rotating frame, or between two rotating assemblies having different speeds or rotational direction, ideal for application in wind turbines.

"Twistact originated by asking ourselves some really challenging questions," said Jeff Koplow, Sandia research scientist and engineer. "We knew it could be game-changing if we could find a way to get around the limited service lifetime of conventional rotary electrical contacts."

"I started thinking that maybe not every conceivable rotary electrical contact architecture has been thought of yet," Koplow said. "We spent a lot of time considering if there was another plausible way."

The resulting innovation, Twistact, uses a pure-rolling-contact device to transmit electrical current along an ultra-low-resistance path. The technology proves beneficial in lowering costs, improving sustainability and reducing maintenance.

Additionally, Sandia's Twistact technology addresses two physical degradation processes common to high-maintenance brush or slip ring assemblies—sliding contact and electrical arcing. These limiting factors reduce the performance of traditional rotary electrical contacts and lead to short operating lifetimes and high maintenance or replacement costs.

Twistact, on the other hand, has been proven through laboratory testing to be capable of operating over the full 30-year service time of a multimegawatt turbine without maintenance or replacement.Other potential applications for the technology include synchronous motors and generators, electrified railways and radar towers. Twistact could also be used in replacing brush or slip rings in existing applications.

https://newsreleases.sandia.gov/turbine_innovation/---------------------------------------------------------------

Reinventing Offshore Wind Turbineshttps://newsreleases.sandia.gov/floating_turbines/ALBUQUERQUE, N.M. — Brandon Ennis, Sandia National Laboratories’ offshore wind technical lead, had a radically new idea for offshore wind turbines: instead of a tall, unwieldy tower with blades at the top, he imagined a towerless turbine with blades pulled taut like a bow.

This design would allow the massive generator that creates electricity from spinning blades to be placed closer to the water, instead of on the top of a tower 500 feet above. This makes the turbine less top-heavy and reduces the size and cost of the floating platform needed to keep it afloat.

For traditional, horizontal-axis wind turbines, the blades can rotate away from intense, damaging winds, but the Darrieus design catches the wind from every direction. The Sandia design replaces the central vertical tower with taut guy wires, Ennis said. These wires can be shortened or lengthened to adjust for changing wind conditions to maximize energy capture while controlling strain. Additionally, replacing the shaft with wires reduces the weight of the turbine even more, allowing the floating platform to be even smaller and less expensive.